Wood & Veneers

Precious woods of the world

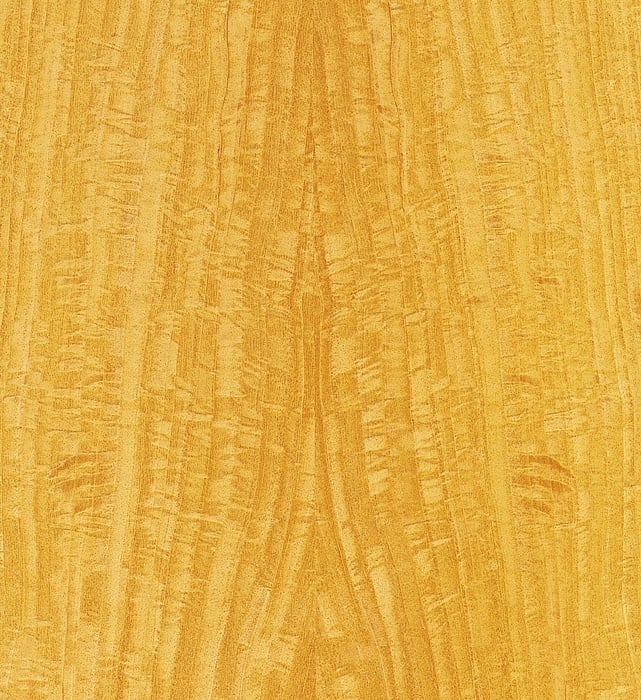

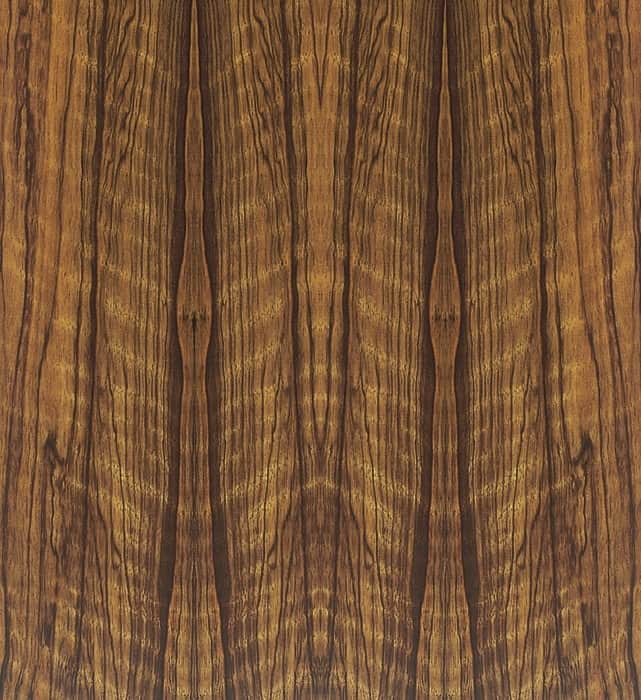

Among the things that these fine woods are known for are: a beautiful and expressive color, striking color contrasts, amazing veins, and other unique embossing effects, especially when compared to “normal” appearing wood. Other characteristics of the wood include a noticeable heft, a high-density, a special resistance to pests, rarity, and a high value.

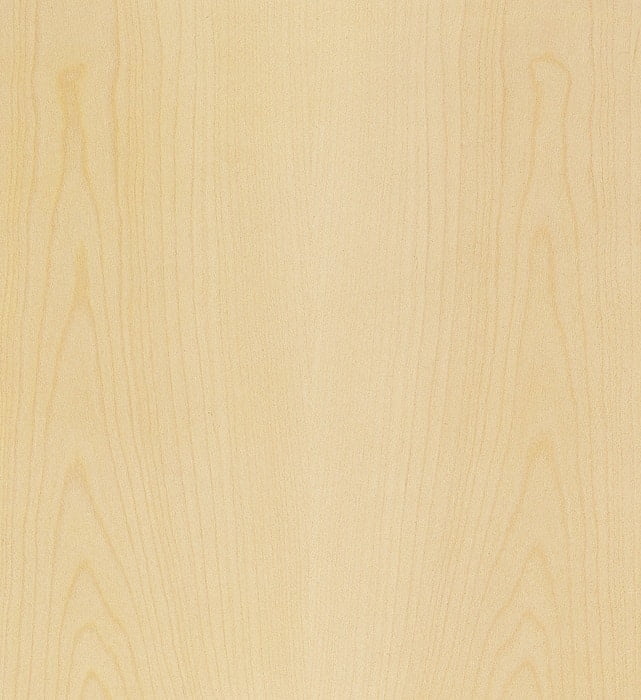

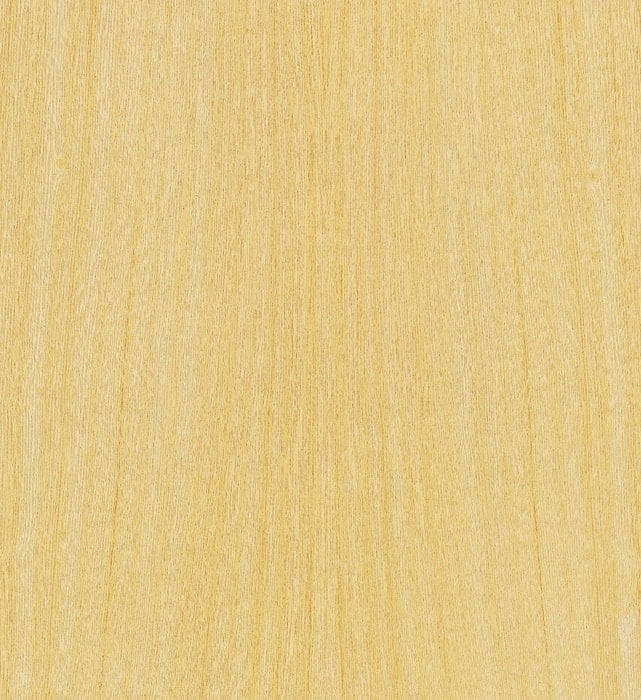

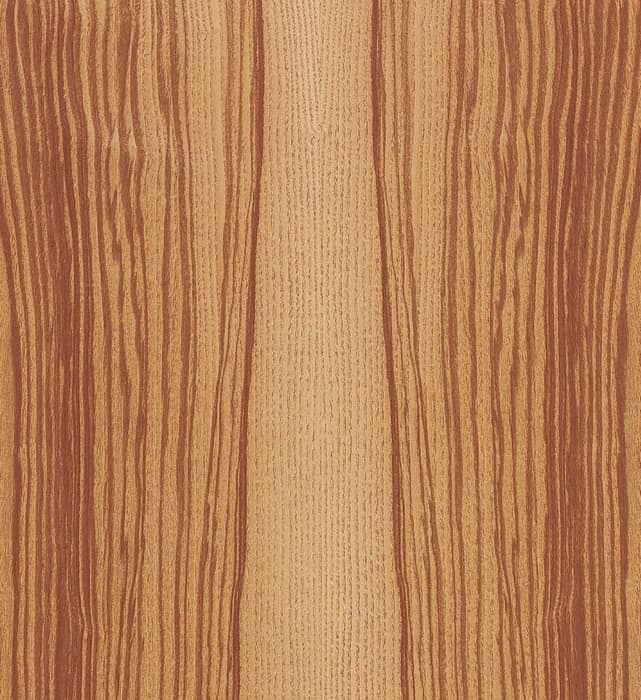

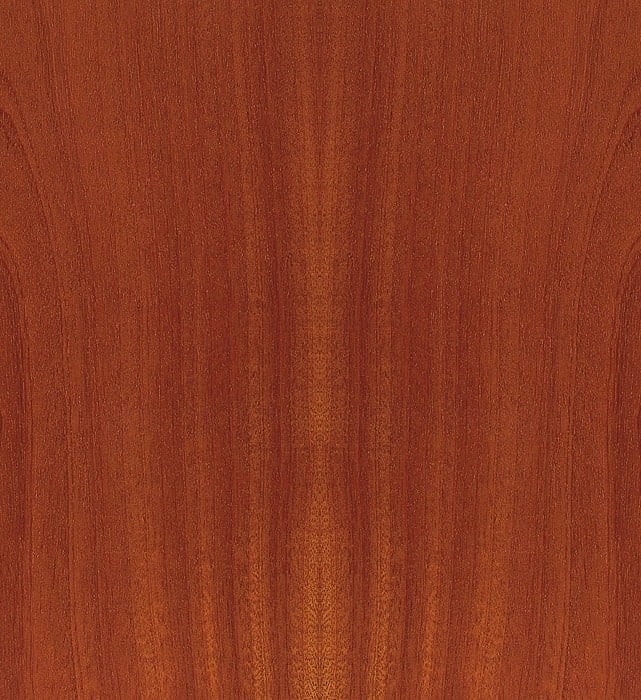

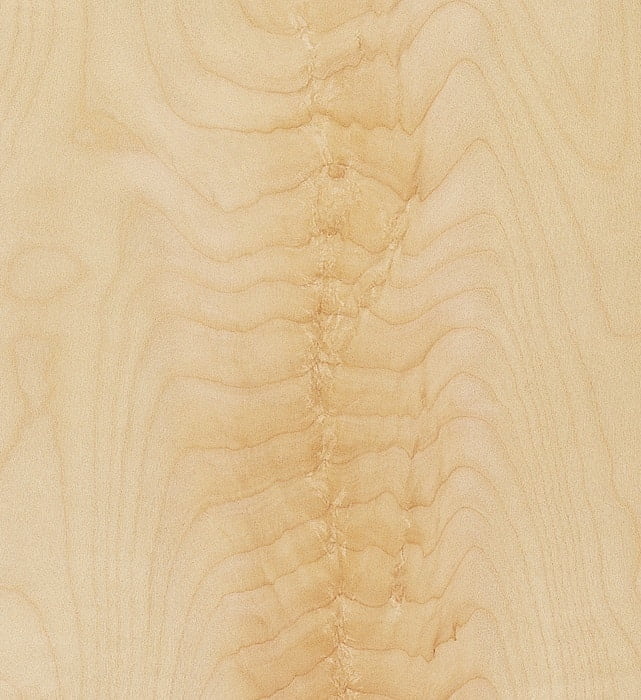

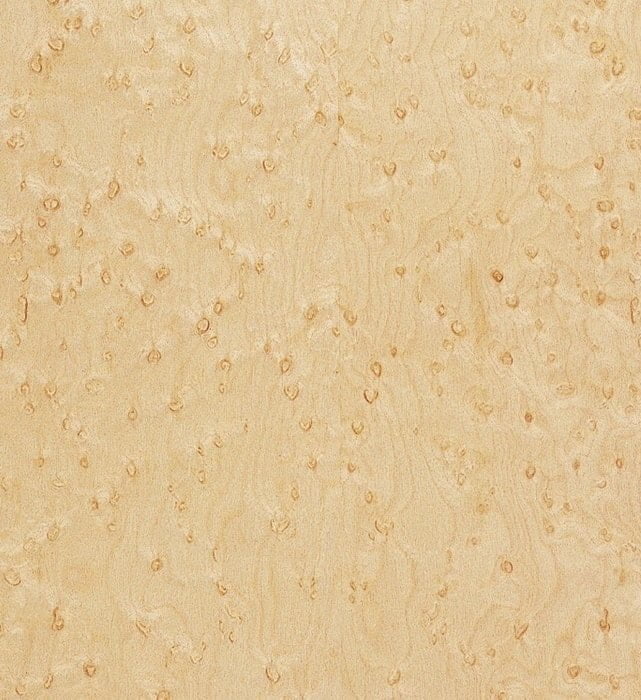

Light veneers

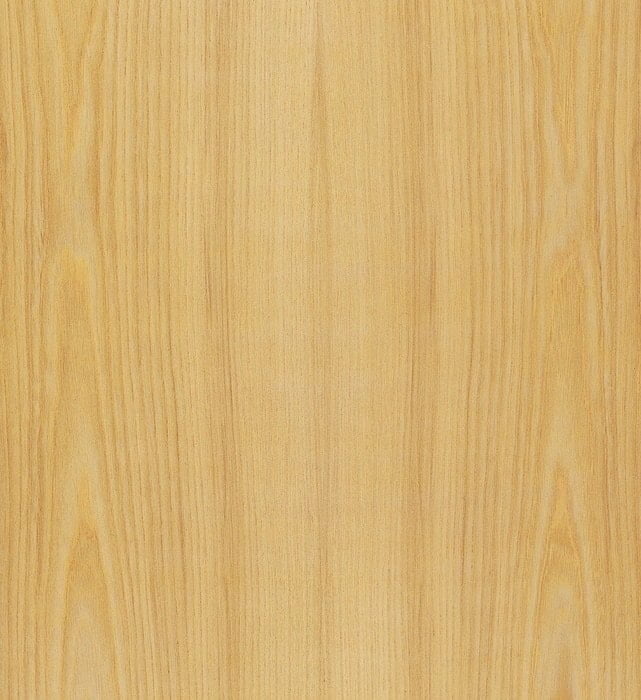

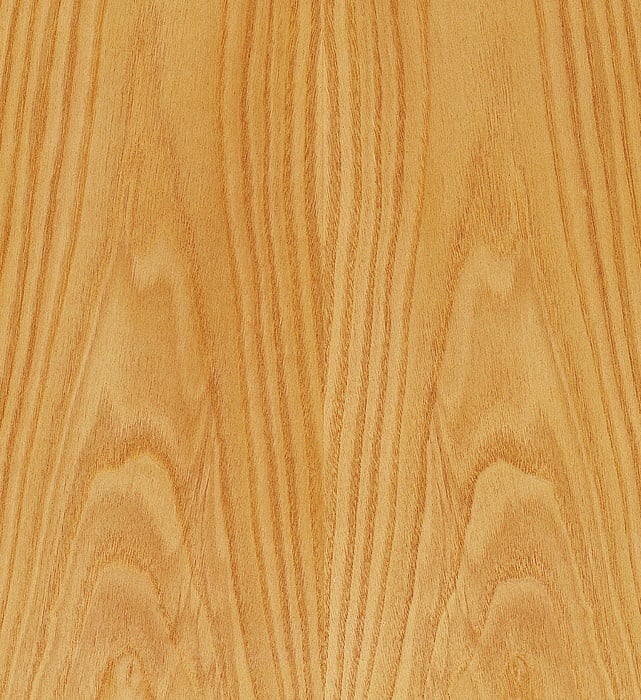

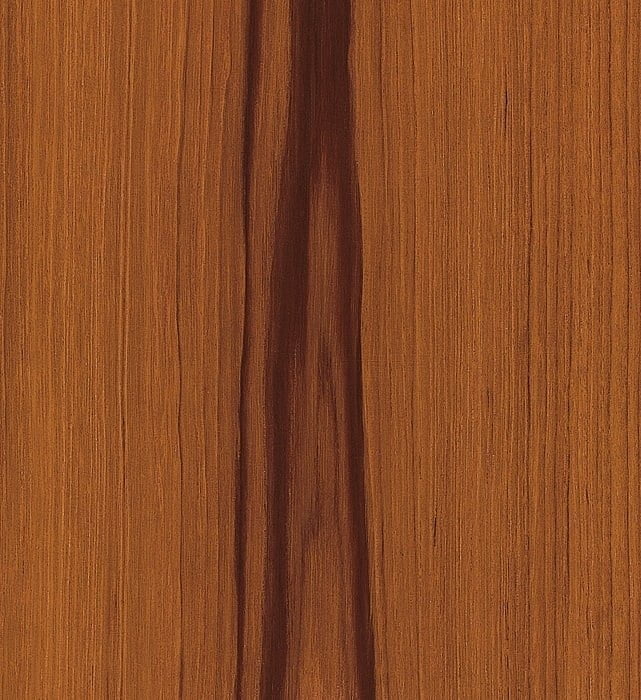

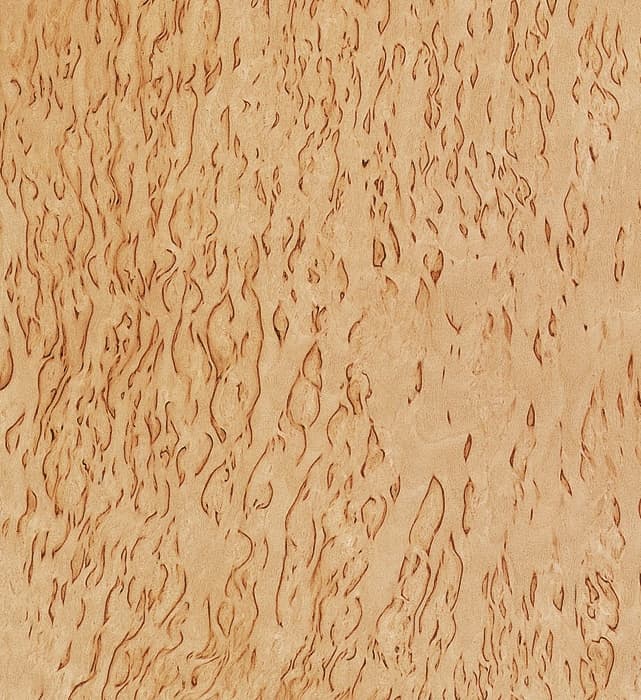

Medium Tone veneers

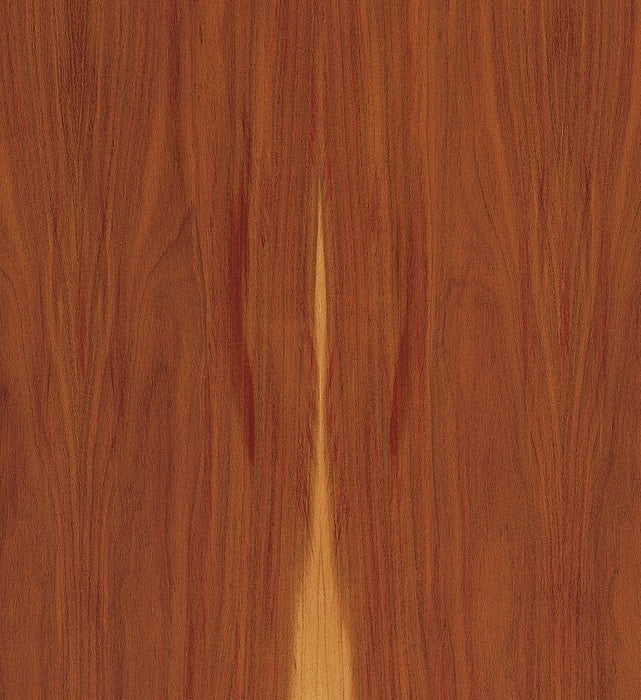

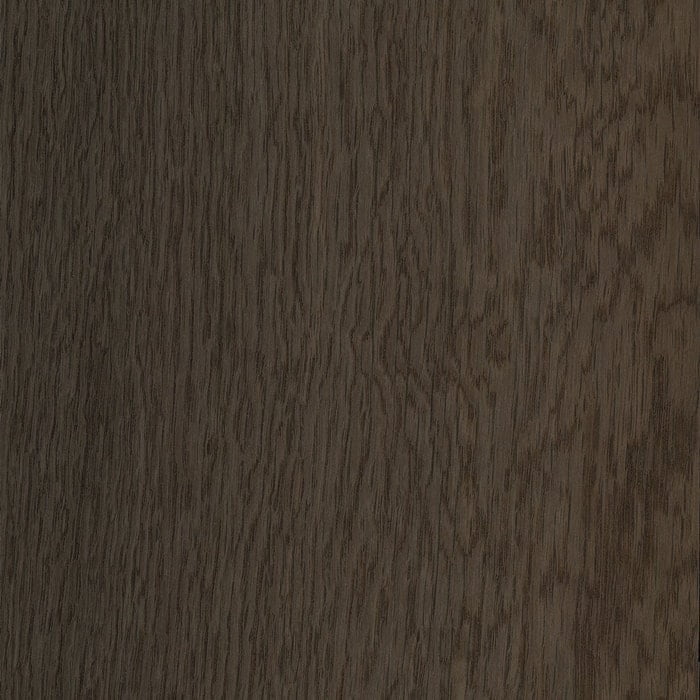

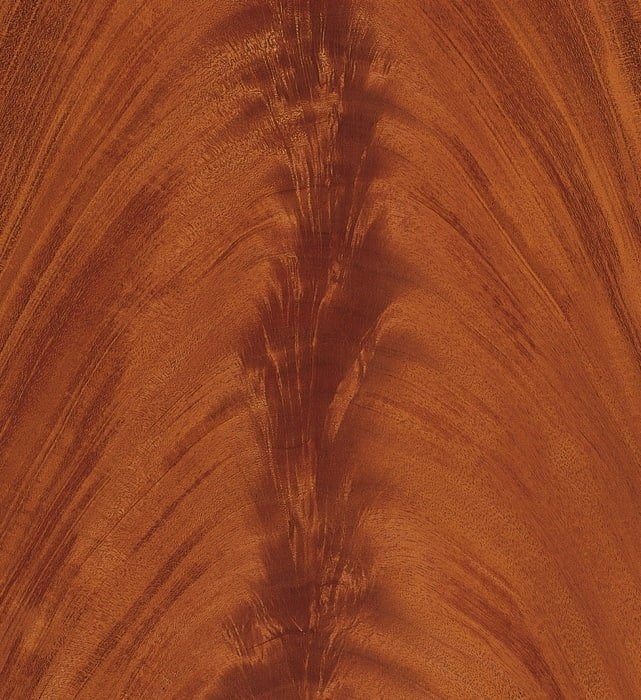

Dark veneers

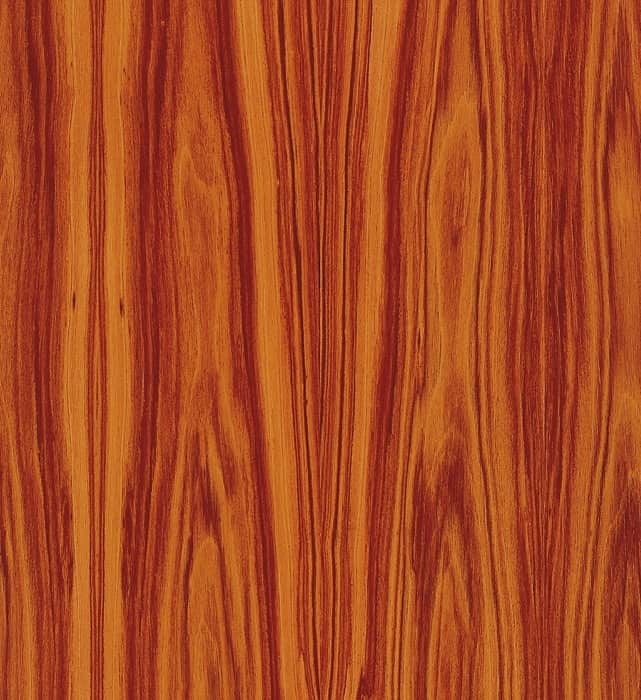

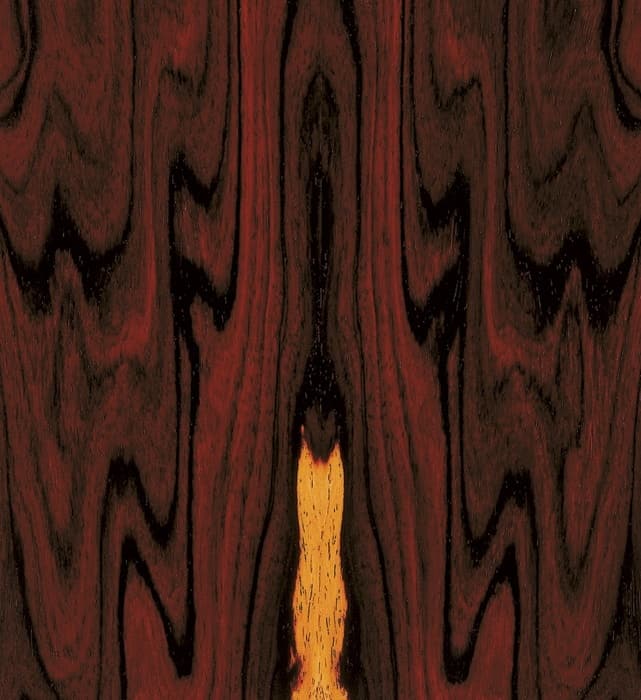

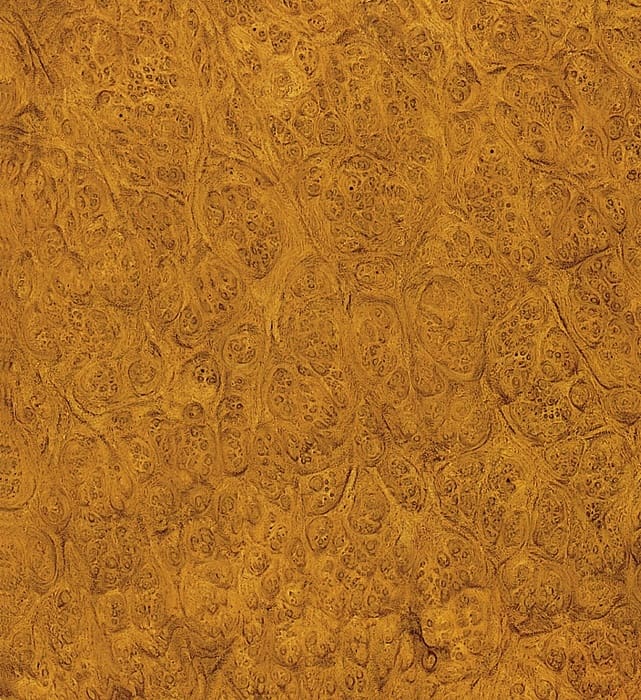

Exclusive Veneers

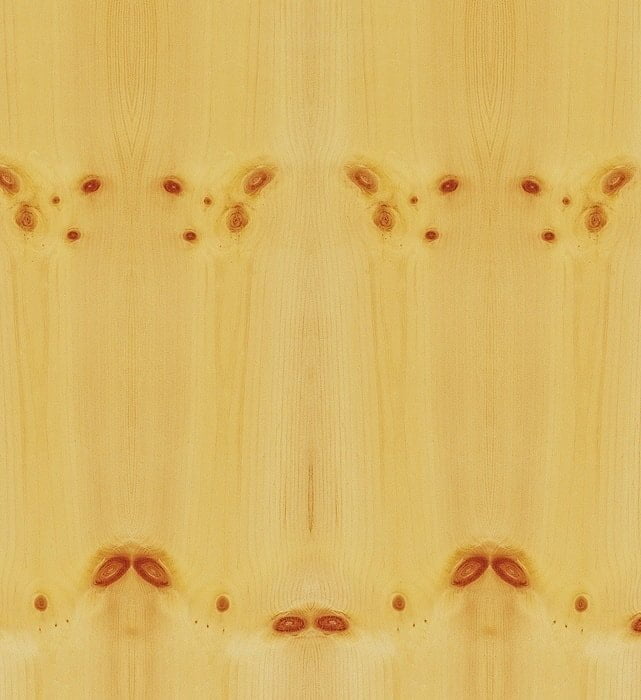

Growth characteristics

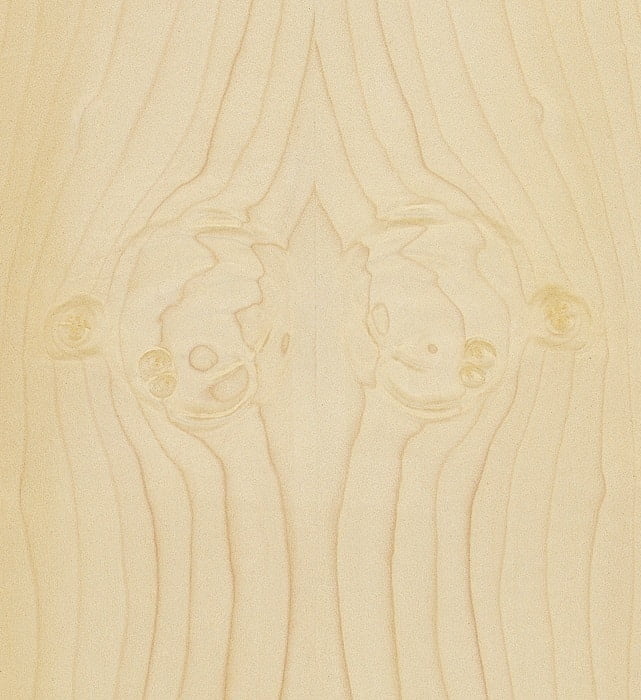

Each type of wood and each piece of wood has individual growth characteristics; therefore, each veneered Gerber humidor is also truly unique. These growth characteristics are not defects, but typical of wood.

Every tree and every type of wood has individual characteristics, such as special grains, small knot growths or interesting color variations. They contribute significantly to its characteristic surface of our Gerber cigar cabinets.

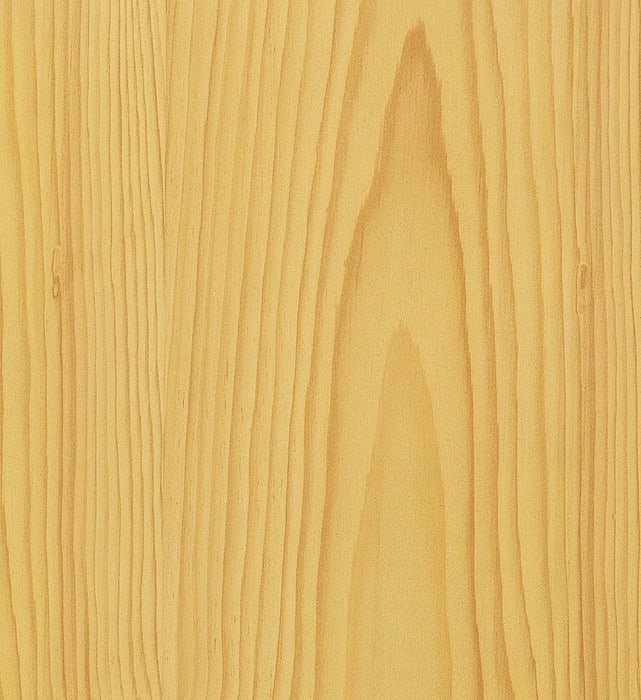

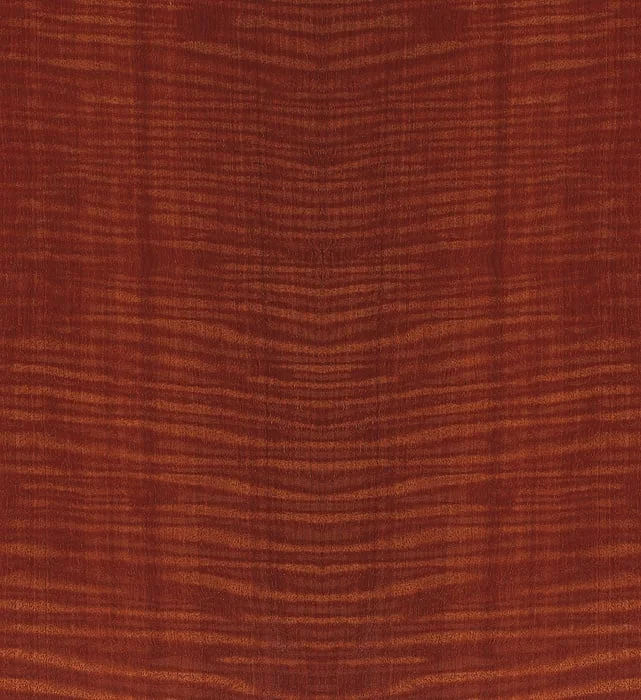

Steamed veneers

Maple, beech or other, especially light-colored, veneers can be produced unsteamed and steamed. By the so-called boiling in hot water two effects are achieved: The wood is given the necessary suppleness to ensure a perfect finishing quality. And the duration of the boiling or steaming process affects the color of the veneer. With some woods, there may be slight pinkish tones in the wood. This ensures the uniqueness and the worldwide unique quality for a genuine Gerber humidor – the best for the best cigar storage.

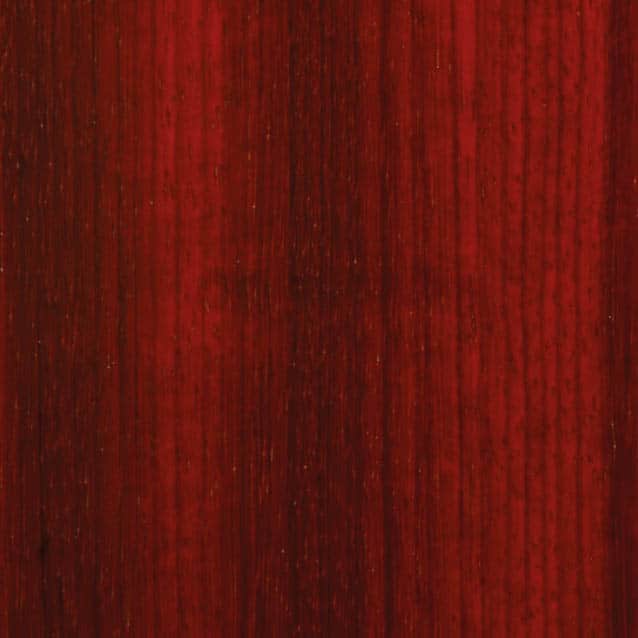

Smoked veneers

Smoking is a staining process used as early as 150 years ago. It involves steaming the wood with ammonia. All woods rich in tannins, such as oak, pine, larch, service tree, apple tree and Douglas fir are suitable for smoking.

The reaction of the acid in the wood with ammonia as a base produces the dark coloration. The discoloration remains absolutely stable to aging and as far as possible to light. Veneers such as smoked oak or smoked eucalyptus are particularly popular with Gerber Humidor customers. Wonderful unique pieces are created for cigar lovers that offer the best in cigar storage worldwide.

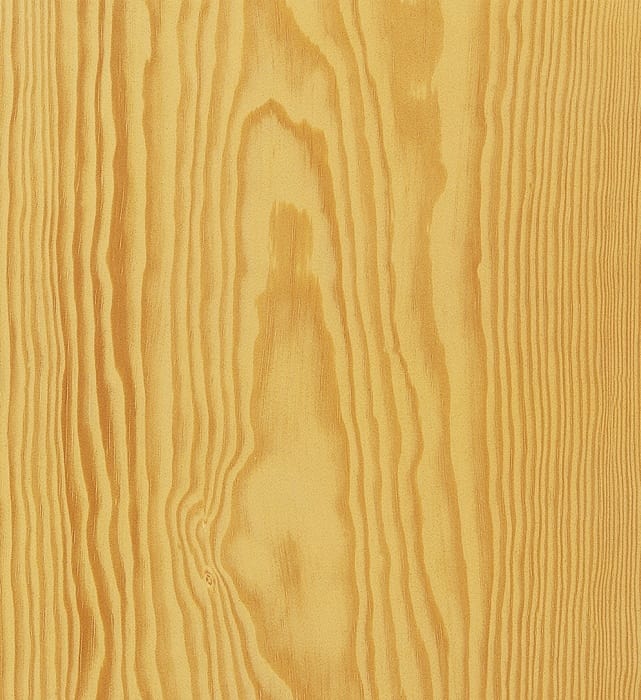

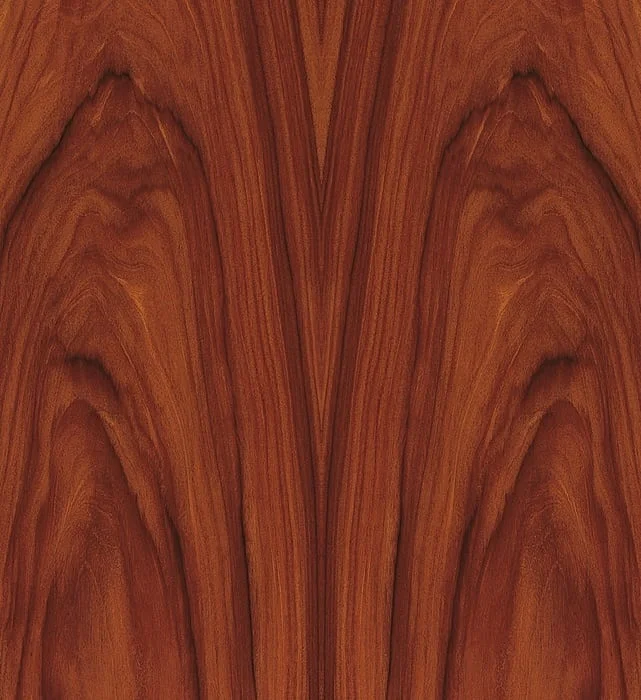

Unwinding

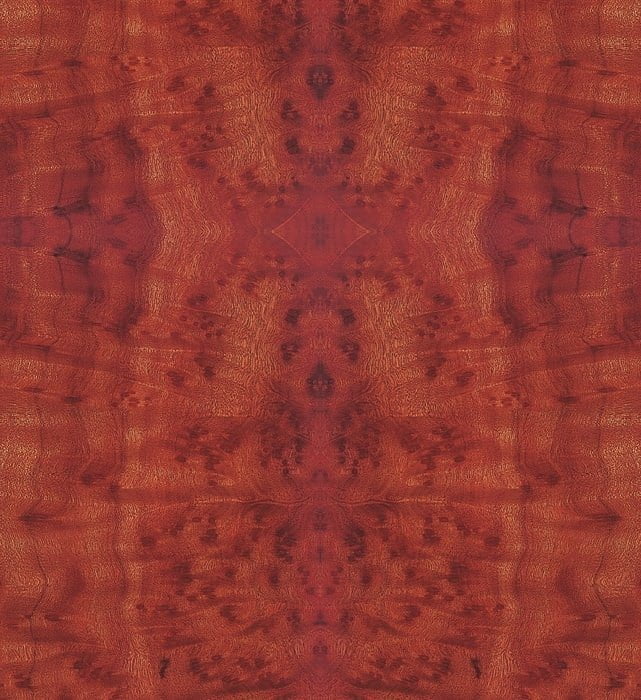

The joining of successive veneer sheets of a bundle or a whole log to form a larger veneer surface is called veneer unwinding or veneer sequence. Most popular for processing fine Gerber humidor woods is the technique of tumbling.

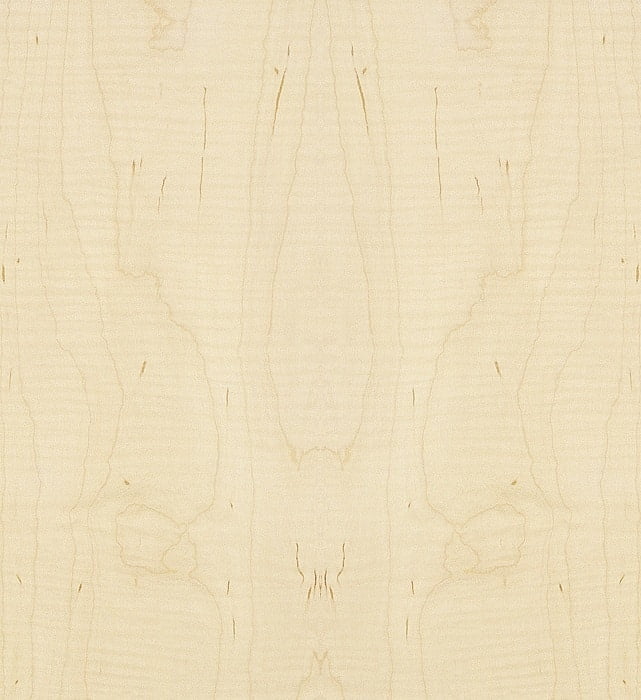

In the process of overturning, the veneers are selected and assembled so that two sheets of veneer face each other in a mirror image (similar to an open book, hence the term „bookmatch“ in English). The mirror image effect is particularly prominent when vividly grained veneers are selected.

Source: IFN, Initiative Veneer and Nature, www.furnier.de